Aluminum round bars represent an extremely versatile solution for numerous industrial and creative sectors. Thanks to their technical, aesthetic, and mechanical characteristics, they have become a key element in applications ranging from precision mechanics to interior design, from furniture to automotive.

What Are Aluminum Round Bars?

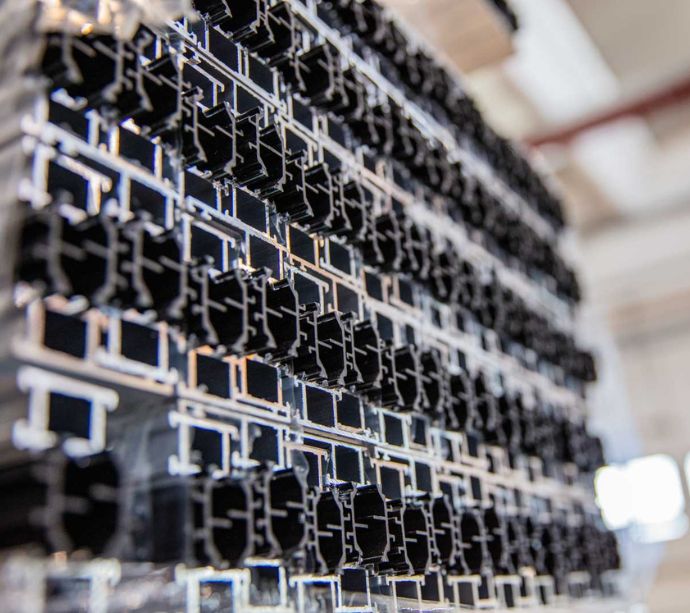

Aluminum round bars are extrusions made from aluminum alloy produced through a process that ensures high strength, lightness, and machinability. Their cylindrical shape makes them ideal for mechanical machining processes such as turning, milling, and drilling. They are supplied in various alloys (such as 6060, 6082, or 7075) depending on specific requirements for strength and workability. Casal Aluminium, also specialized in supplying small-sized extrusions, offers a wide range of round bars designed to meet the needs of different sectors, from large-scale aluminum distribution to electromechanical, mechanical, and furniture applications. Thanks to the quality of the materials used, these bars provide excellent corrosion resistance, making them suitable for both indoor and outdoor environments, even in the presence of humidity. The aluminum used is lightweight, easy to handle, and easy to work with: this simplifies operations such as cutting, bending, and shaping the bars. Despite their lightness, they maintain good mechanical strength, allowing their use in applications that require structural solidity. Additionally, the smooth and even surface is suitable for aesthetic or functional treatments, making these extrusions perfect for finishing and design work.Main Advantages of Aluminum Round Bars

- Lightness and Strength: Aluminum offers an excellent strength-to-weight ratio.

- Reduced Corrosion: Ideal for outdoor and humid environments, even without special treatments.

- Ease of Machining: Perfect for complex mechanical parts thanks to the material’s ductility.

- Aesthetic Finish: Aluminum lends itself well to surface treatments (anodizing, polishing) ideal for design.

- Recyclability: 100% recyclable, promoting environmental sustainability.

Applications in Various Sectors

Mechanical Engineering and Industry

In the mechanical parts sector, aluminum round bars are used to manufacture high-precision components, shafts, bushings, spacers, and supports. Their lightness reduces the load on machines and improves performance.Furniture and Design

More and more designers choose aluminum to create lightweight and modern structures, thanks to its ability to be shaped and finished elegantly. Round bars are used in furniture elements, lamps, supports, and accessories.Automotive Sector

The automotive industry employs aluminum round bars to improve vehicle efficiency by reducing overall weight without compromising strength. They are used to produce structural components, fittings, and chassis parts.Why Choose Aluminum Extrusions?

Choosing aluminum extrusions means investing in reliable, lightweight, and easy-to-work materials. Round bars, in particular, represent an effective solution for any requirement where precision, aesthetics, and functionality are needed. Thanks to their versatility, aluminum extrusions adapt to a wide range of applications, from industrial components to architectural and decorative solutions. Aluminum is also a fully recyclable material, making it a sustainable and modern choice. Casal Aluminium offers the possibility to customize each extrusion according to specific project requirements, following detailed technical drawings and guaranteeing tighter tolerances than European standards. The entire process is overseen by qualified technical staff to ensure reliability, certified quality, and punctual deliveries.Available Surface Treatments

Aluminum round bars can undergo various surface treatments that enhance their technical performance and aesthetics. Some of the most common treatments include:- Anodizing: An electrochemical process that creates a protective oxide layer on the aluminum surface, increasing corrosion resistance and allowing for customizable aesthetic effects, such as matte or glossy finishes.

- Painting: Allows the application of a colored protective layer on the metal surface, improving resistance to weathering and offering a wide range of visual finishes, both glossy and satin.

- Brushing and Polishing: Mechanical treatments that make the surface more uniform, smooth, or shiny, ideal for applications where design is a key element, such as in furniture or the lighting sector.

Sustainability and Product Life Cycle

Aluminum is one of the most sustainable materials available on the market, and aluminum round bars are a concrete example of this. This metal is fully recyclable without any loss of quality and can be melted down infinitely with a significantly lower energy impact compared to primary production. This aspect makes aluminum a strategic choice for companies focused on reducing environmental impact. Once used, round bars can be reintroduced into the production cycle, thus contributing to circular economy models. Moreover, their long lifespan combined with corrosion resistance reduces the need for frequent replacements and further lowers the environmental cost throughout the product's entire life cycle. Investing in aluminum therefore means not only choosing high performance but also promoting a more responsible and future-oriented production culture.Technical Expertise and Customization

Relying on a company experienced in aluminum processing ensures products that comply with European standards and are suitable for professional applications. Casal Aluminium stands out for its specialization in small-sized extrusions, including round bars, and for the ability to customize profiles based on specific technical drawings, with tighter tolerances than EU standards. This is complemented by particular attention to compliance with European regulations regarding strength and safety, guaranteeing reliable and durable products. The technical support offered by the company accompanies the customer through all project phases, up to delivery within the agreed timeframes.Request a Consultation for Your Aluminum Project

If you are looking for aluminum round bars or custom-made extruded profiles, Casal Aluminium is the ideal partner to support you at every stage of the process, from selecting the most suitable alloy to the final customization. We offer:- Expert and targeted technical support

- Production according to drawings with tight tolerances

- Careful selection of alloys and surface treatments

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]