Aluminum profile rolling is one of the most sophisticated industrial processes in metalworking, essential for producing aluminum profiles with superior technical, aesthetic, and functional characteristics. This specialized technique transforms raw aluminum into complex structures and high-quality decorative elements used across various industries. Utilizing advanced machinery and skilled operators, roll forming achieves aluminum profiles with enhanced technical features and customized finishes. Let’s explore how roll forming works and why it’s a benchmark in modern processing technologies.

What is Aluminum Profile Rolling and How Does It Work

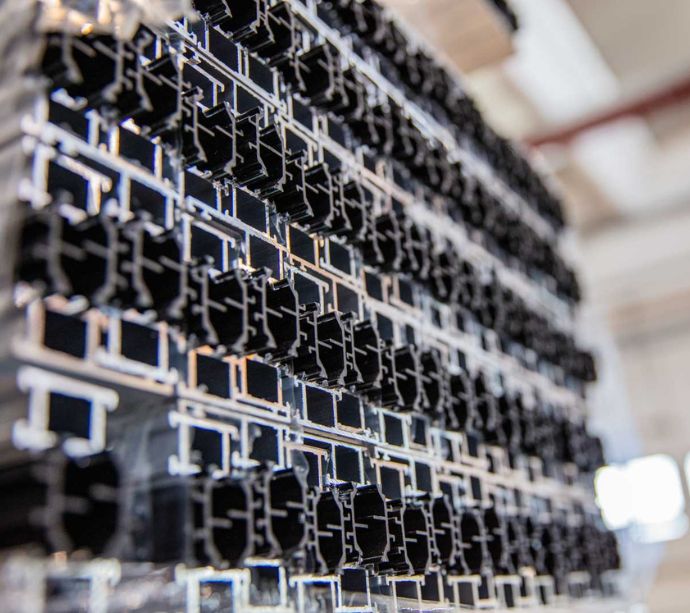

Aluminum profile rolling is a cold plastic deformation process that uses advanced roll forming machines to shape aluminum with high precision. The process begins by feeding aluminum, available as coils or bars, into the roll forming machine. These sophisticated machines are equipped with specially designed rotating rollers that, through calibrated pressure, compress and shape the metal according to predefined technical specifications. The configuration and shape of the rollers vary based on the desired profile, ensuring a wide range of production possibilities. Each roll forming machine is designed to ensure minimal tolerances and consistent shapes, adaptable to a vast array of technical specifications. Computerized control allows precise management of parameters like pressure, speed, and deformation sequence, making the process highly efficient. A fundamental aspect of roll forming is the ability to finely adjust operational parameters. This flexibility enables the production of aluminum profiles with customized technical characteristics, effectively meeting the specific needs of each project. During the process, various surface finishes can also be applied, from matte to glossy, further expanding customization options.Advantages of Aluminum Profile Rolling

Aluminum profile rolling offers numerous advantages over other metalworking techniques, making it a preferred choice for many industrial applications. One of the main benefits is the exceptional wear resistance of the products obtained through this process. Rolled profiles exhibit excellent mechanical properties and long-term durability. Another significant advantage is dimensional precision. This process allows for aluminum profiles with extremely tight tolerances and strictly controlled dimensions, crucial in sectors where precision is essential. The ability to maintain high and consistent quality standards throughout production is a distinctive feature of aluminum profile rolling. Design versatility is another strength of this technique. Roll forming enables the creation of decorative and technical elements with complex geometries, offering designers extensive creative freedom. This versatility translates into the ability to develop tailored solutions for specific applications, surpassing the limitations of other production methods. Additionally, the process offers advantages in production efficiency. Roll forming eliminates several additional processing steps, significantly reducing overall production times. This process optimization results in greater market competitiveness, both in terms of costs and delivery times.

Applications of Rolled Aluminum Profiles

Rolled aluminum profiles find applications in numerous industrial sectors due to their excellent mechanical properties and aesthetic versatility. In construction, these elements are widely used for making frames, doors, windows, façade systems, and other aluminum structures. The combination of lightness, corrosion resistance, and durability makes rolled aluminum profiles particularly suitable for these applications. In the furniture and design sector, rolled profiles are used to create decorative elements with significant aesthetic impact. The ability to achieve various surface finishes and complex shapes allows designers to develop innovative and customized solutions, meeting the sophisticated demands of the contemporary market. The transportation industry is another important application area. Rolled aluminum profiles are used in constructing components for road, rail, and marine vehicles, where the combination of lightness and mechanical strength is fundamental. Reducing the overall weight of transport vehicles leads to lower fuel consumption and reduced pollutant emissions. The energy and renewable energy sectors also benefit from using aluminum structures made through roll forming. These components are used in constructing solar panels, support systems for wind turbines, and other applications where resistance to atmospheric agents and durability are critical factors.The Role of Roll Forming Machines in Aluminum Processing

Roll forming machines are the technological core of the aluminum profile rolling process. These advanced machines are specifically designed to ensure maximum precision and repeatability during metal processing. A modern roll forming machine comprises several fundamental elements: a material feeding system, a set of configurable rollers, and a computerized control system that constantly monitors and adjusts operational parameters. The quality and configuration of the rollers are crucial in determining the final characteristics of the profile. These components can be made from various materials, generally special heat-treated steels to ensure hardness and wear resistance. The geometry of the rollers is precisely designed based on the desired aluminum profile and can be modified to meet specific production needs. Modern roll forming machines' control systems utilize advanced technologies to ensure maximum precision throughout the process. Finishes and Post-Rolling Treatments Once the roll forming process is complete, aluminum profiles can undergo various surface treatments to further enhance their aesthetic and functional properties. Among the most common finishes is anodizing, an electrochemical process that creates a protective layer on the aluminum surface, increasing corrosion resistance and enabling the application of different colors. Painting is another frequently used method to customize the appearance of aluminum profiles. This treatment allows for a wide range of colors and finishes, from matte to glossy, effectively meeting diverse aesthetic demands. Modern powder coating techniques also ensure excellent resistance to weathering and wear. For applications requiring specific surface characteristics, sandblasting or brushing treatments may be applied. These processes alter the surface roughness of the metal, creating unique aesthetic effects and improving specific functional properties such as grip or slip resistance. The combination of roll forming and surface treatments results in aluminum elements with superior technical and decorative qualities. How to Choose a Specialized Aluminum Profile Rolling Supplier Choosing a reliable partner for aluminum profile rolling is a crucial factor for the success of any project requiring these components. A specialized supplier should have proven industry experience, supported by a portfolio of completed projects and positive references from previous clients. The company’s longevity in the market is often an indicator of its reliability and the quality of services offered, including the production of aluminum profiles. The technical skills of the personnel are another fundamental aspect to consider. Aluminum profile rolling requires specialized knowledge and a high level of expertise that only properly trained operators can guarantee. A quality supplier continuously invests in staff training to ensure that competencies remain up to date with the latest technological innovations in the field. Technological infrastructure is another key differentiator. A cutting-edge aluminum rolling company is equipped with modern machinery and advanced control systems that guarantee maximum precision and repeatability throughout the production process. The ability to offer custom solutions, adapting processes to the client’s specific requirements, also represents a significant added value. Finally, reliable delivery times and high-quality customer service complete the profile of an excellent supplier. Timely fulfillment of agreed deadlines and the availability to provide technical support throughout all project phases can make a real difference—especially in projects with tight schedules or complex requirements. Innovations and Future Trends in Aluminum Profile Rolling The aluminum profile rolling sector is constantly evolving, driven by technological innovation and growing market demands. Modern roll forming machines integrate advanced digital technologies that monitor every phase of the process in real time, improving precision, enhancing efficiency, and reducing waste. This results in the production of high-quality aluminum profiles with optimized performance. Another key factor is sustainability: the industry is adopting energy-efficient techniques and recycling aluminum, thereby reducing environmental impact and CO₂ emissions. Research is also focusing on developing new aluminum alloys with improved mechanical properties, ideal for roll forming applications. These alloys allow for the production of lighter and more resistant profiles, suitable for sectors such as aerospace and biomedical, as well as for high-performance aluminum structures. Even the creation of decorative elements benefits from these new alloys, with enhanced aesthetic and functional results. In conclusion, aluminum profile rolling is a mature yet continuously developing technology, combining precision, versatility, and sustainability. Thanks to digitalization and ongoing research, aluminum metalworking remains central across numerous industrial sectors. Aluminum profile rolling remains a well-established yet dynamic technology, capable of adapting rapidly to current and future challenges. With the advancement of digital tools, the push for sustainability, and the development of new materials, this process is now more relevant than ever in modern metalworking. Its ability to combine precision, versatility, and environmental responsibility makes roll forming an ideal solution for the production of structural components and decorative elements in aluminum, used in a wide range of industrial applications. Would you like to discover how aluminum profile rolling can add value to your projects? Get in touch with us: the CasalAluminium team is here to provide personalized consultation, advanced technical solutions, and extensive expertise in metal processing, aluminum structures, and decorative elements.

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]