Here are our aluminium alloys with their mechanical properties

Aluminum alloys are distinguished by their extraordinary versatility, strength, and reliability. These characteristics make them highly valued and widely used in fields such as engineering, construction, and the automotive industry, positioning them among the most commonly used metallic materials alongside steel. Although aluminum, in its pure form, offers remarkable qualities, its strength may not be sufficient for long-term applications. To overcome this limitation, it is combined with other elements to create alloys that are far more durable and ideal for industrial use. In particular, aluminum alloys are essential when there is a need to reduce the weight of a product, such as an airplane, without compromising structural integrity. In this article, we will delve deeper into what aluminum alloys are, how many types exist, and their mechanical properties with various forms and applications.What are aluminium alloys?

To understand what aluminum alloys are, it is useful to recall the extraordinary properties of this metal. Known for its strength, lightness, flexibility, and versatility, it is used in numerous industrial sectors and stands out as an excellent alternative for various applications such as insulation, electrical and thermal conductivity, mechanical construction, and prototype development. An aluminum alloy is a combination of various metallic elements, designed to enhance the properties of the base material, such as strength and durability. In the case of aluminum alloys, the main metal is aluminum itself, to which elements such as silicon, tin, manganese, copper, or magnesium are added depending on the specific requirements of use. Thanks to a careful selection of components, an aluminum alloy can become significantly stronger and, under certain conditions, even offer better performance than steel.What are the different types of aluminium alloys?

Aluminum alloys are divided into eight main numerical series, based on their composition, each possessing specific mechanical and chemical properties. Used in numerous industrial fields, here are the main categories:- Series 1xxx – Pure aluminum: a composition with 99% aluminum, containing traces of other elements such as silicon, iron, and copper.

- Series 2xxx – Aluminum-copper alloys: a composition with copper as the main element, between 3% and 6%, along with small amounts of manganese, silicon, and other metals.

- Series 3xxx – Aluminum-manganese alloys: main component manganese, between 1% and 2%.

- Series 4xxx – Aluminum-silicon alloys: main component silicon, up to 13%.

- Series 5xxx – Aluminum-magnesium alloys: main component magnesium, up to 5%.

- Series 6xxx – Aluminum-magnesium-silicon alloys: main components magnesium and silicon.

- Series 7xxx – Aluminum-zinc alloys: main component zinc, up to 12%.

- Series 8xxx – Special alloys: a variable composition that includes elements such as lithium, iron, lead, boron, and titanium.

Electrical properties and thermal capacity of aluminium alloys

As mentioned in the previous section, each of these aluminum alloys has specific mechanical properties that make them suitable for various industrial applications. Let’s take a look at the characteristics of each aluminum alloy:- Series 1xxx – Pure aluminum: ductile and easy to work, high corrosion resistance, especially against water and acids, good thermal and electrical conductivity, but low mechanical strength compared to other aluminum alloys.

- Series 2xxx – Aluminum-copper alloys: excellent mechanical strength, but low corrosion resistance, especially in marine or humid environments; outstanding toughness and fatigue resistance.

- Series 3xxx – Aluminum-manganese alloys: excellent corrosion resistance, particularly in marine environments, good oxidation resistance and workability, but moderate mechanical strength, making them suitable for non-structural applications.

- Series 4xxx – Aluminum-silicon alloys: a casting alloy with excellent fluidity, ideal for casting production, very good weldability, but moderate corrosion resistance.

- Series 5xxx – Aluminum-magnesium alloys: excellent corrosion resistance, particularly in marine environments, good mechanical strength, high fatigue resistance and stress corrosion resistance.

- Series 6xxx – Aluminum-magnesium-silicon alloys: good corrosion resistance, excellent workability and formability, high mechanical strength when heat-treated.

- Series 7xxx – Aluminum-zinc alloys: very high mechanical strength, one of the strongest aluminum alloys, high fatigue and impact resistance, but low corrosion resistance, particularly in marine environments, requiring protective treatments.

Casal Aluminium's aluminium alloys

Casal Aluminium is a benchmark company for aluminum alloys, recognized for its innovation and wide range of proprietary alloys available to customers. All aluminum alloys used by Casal Aluminium are classified as light alloys and comply with the UNI EN 573-3 standard, which defines the chemical composition limits of semi-finished aluminum products and alloys as well as their product form. Here are the available alloys:- EN AW-1070A: Alloy with aluminum as the main element.

- EN AW-6060: Alloy with aluminum, magnesium, and silicon.

- EN AW-6005: Alloy with aluminum, silicon, and magnesium.

- EN AW-6005A: Alloy with aluminum, silicon, and magnesium.

- EN AW-6061: Alloy with aluminum, magnesium, and silicon.

- EN AW-6063: Alloy with aluminum, magnesium, and silicon.

- EN AW-6063A: Alloy with aluminum, magnesium, and silicon.

- EN AW-6082: Alloy with aluminum, silicon, magnesium, and manganese.

- EN AW-6101: Alloy with aluminum, magnesium, and silicon.

- EN AW-6101B: Alloy with aluminum, magnesium, and silicon.

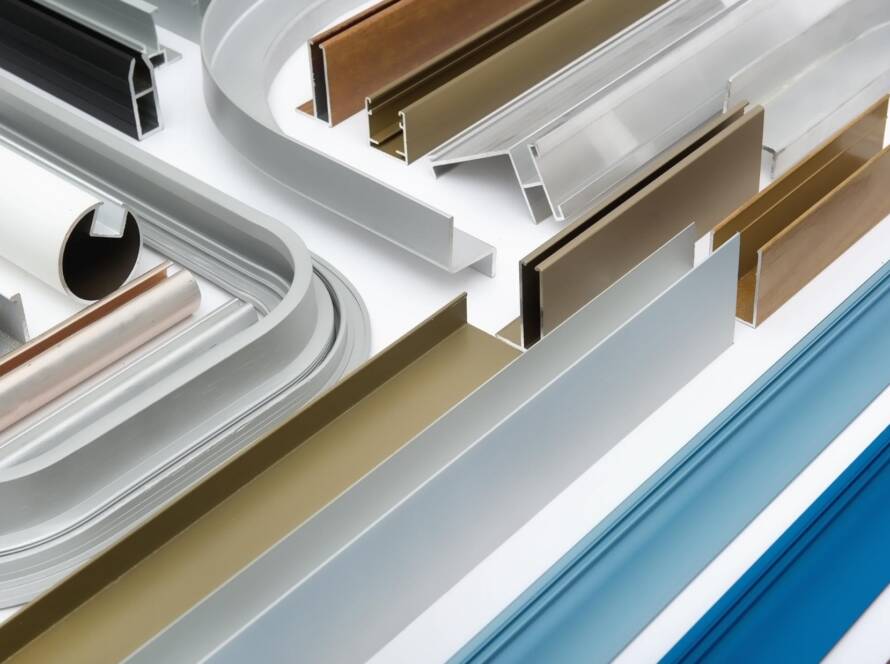

Aluminium alloys: Applications and shapes

Aluminum alloys are used in a wide range of shapes and applications, thanks to their unique mechanical properties: they are lightweight, corrosion- and mechanically resistant, and easy to process. Each shape is designed for specific processing and performance needs. Below are the main forms of aluminum alloys:- Aluminum plates: Thin metal sheets with thicknesses ranging from a few millimeters to several tens of millimeters. Used in the automotive industry (e.g., for body panels), the aerospace sector, household appliance manufacturing, as well as for facade cladding, interior design, and architectural components.

- Aluminum sheets: A very thin material with a thickness of less than 0.2 mm, primarily used for thermal and non-thermal packaging (e.g., food foils), in electronics for heat sinks, and in thermal and acoustic insulation.

- Aluminum bars: Long, solid segments in rectangular, square, or cylindrical shapes. Used in construction, mechanical components such as gears and axles, machining and milling processes, and for applications requiring high mechanical resistance, such as engine parts, vehicle frames, and industrial structures.

- Aluminum tubes: Cylindrical materials with thin or thick walls, produced through extrusion and available in various lengths and diameters. Used in hydraulic systems, water and gas pipelines, ventilation systems, and in the automotive industry for cooling circuits.

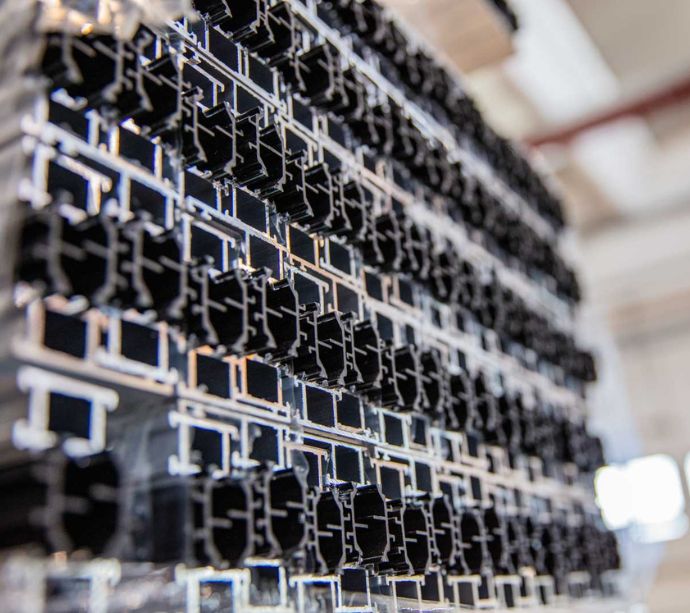

- Profiles: Constant-section extruded aluminum shapes, including T, L, and U profiles, as well as angular and tubular shapes. Used in major construction projects, window and door frames, automotive lightweight component design, as well as in furniture design, hardware, and electronic devices.

- Billets: Solid and compact aluminum blocks, later processed through extrusion, forging, or rolling. Used as raw material to produce bars, profiles, plates, and cast components, essential for structural applications.

- Aluminum casting: A process that allows the production of sophisticatedly shaped components by pouring molten metal into molds. Foundry alloys are designed to ensure good fluidity and low porosity formation. Used in automotive parts such as engines and frames, aerospace structures, mechanical equipment, and industrial machinery.

- Extrusion: A process that enables the production of aluminum alloys in continuous profile sections, such as bars, tubes, and complex shapes. Ideal for hydraulic systems, window and door components, vehicle and aircraft hulls, lightweight structures, and solar panel profiles.

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]